For many fruit and vegetable growers and packers, it is not enough to simply wash the product but it might be necessary to process it as well, for example, peeing and slicing.

One company that has specialised for the last 10 years in meeting these needs is Prima (Food Processing Solutions) Limited.

Based in Gosberton, near Spalding in the heart of a vegetable growing area with a major logistics network for the distribution of fruit and vegetables nationwide, the company acts as agents for three major manufacturers – PND srl of Naples in Italy, Tecnocean from Northern Italy and DWS from Worcestershire. Tony Sheppard set the Company up, back in 2001 and, today, it is run by joint managing directors Tony and his wife, Coleen. Tony says, “We have recently taken on a new company but already it is proving very successfully, namely the agency for PND but already word has got around and we are now taking our first orders.

Their equipment allows us to wash, peel and cut such fruit as pineapples, melons, oranges, apples, kiwi fruit and pears. One of the great advantage of these machines is that they have been carefully designed to extract the maximum amount of saleable product from each piece of fruit, thereby increasing yield and reducing the amount sent to waste.”

The third company is Tecnocean that makes machinery for salad and vegetable processors. This includes, for example the preparation of lettuces, separating the leaves and washing them, cutting them up and drying them.

DWS is an English company that manufactures weighing machinery. It tends to specialise in the weighing of difficult products, soon as fresh (delicate) and frozen fruit or sticky materials, such as ready-meals and mayonnaise-based products such as potato salad and coleslaw. Many machines are produced to weigh volumetrically but DWS machines are designed to weigh even difficult products to average weight standards and exact weights with accuracy. Not only does this save money but it is also vitally important in another way – the amount of protein in a particular food can be critical and if there is too much or not enough, this can infringe standards and therefore the accuracy of weighing is critical.

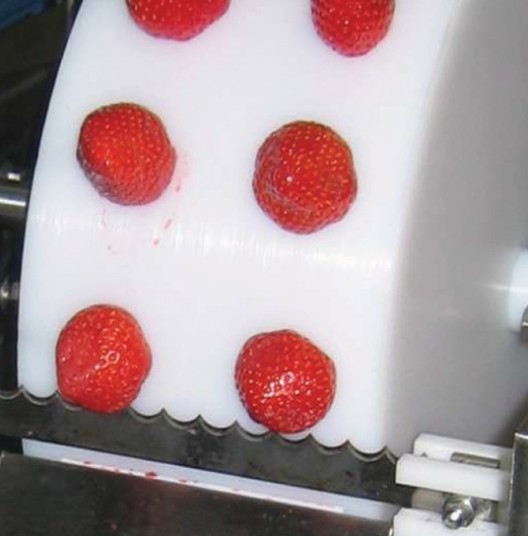

Prima also works to develop new machines with our manufacturers and one such project is a unique development, which will minimise labour costs in the preparation of fresh cut strawberries. The system is capable of decalyxing, halving and quartering a wide range strawberry types and sizes. The compact machine is able to be operated by one operator and achieve speeds of 50 to 60 strawberries / minute. It is possible to connected machines together for higher capacities with conveyors to ease loading and collection of the cut fruit. Complete removal of calyx and leaves is attained, thus presentational quality is very high whilst maintaining minimum wastage. The system is easily moved into and out of area’s to suit production requirements.

Tony says, “Generally we are working in the UK and Ireland. However, we have worked with other companies and also supplied UK companies that have operations in other parts of the world. By this means, we have supplied machinery to Greece, America and South Africa. We have also supplied directly to a customer in Sweden. We will only do this if the manufacturer is not represented in that country, as we do not want to interfere in other companies’ territories.”

Prima also offers other types of equipment and machinery in the food processing industry covering a vast range of functions. The list is plentiful from pepper corers to grilling machines. Conveyor belts and elevators can also be supplied custom built to suit the needs of the customer’s factory layout and space restrictions. Smaller pieces of equipment can also be supplied such as preparation tables etc.

Tony concludes, “We have built the business up over the last 10 years, including our service and spares operation. However, like many other companies, we have been affected by the recession. Despite this, we are finding that things are now beginning to pick up again and we are hoping for an increased turnover in the year to 31 March 2012.”

For further information please telephone 01775 841664 or visit www.primafps.co.uk